Professional systems for renovating pipes and sewers

Sewer systems are exposed to a variety of stresses as they are in permanent use. But also due to errors during transport and installation of the pipes as well as subsequent external loads on the pipes, damage that impairs the functionality occurs over time and can lead to the destruction of the pipelines over the long term.

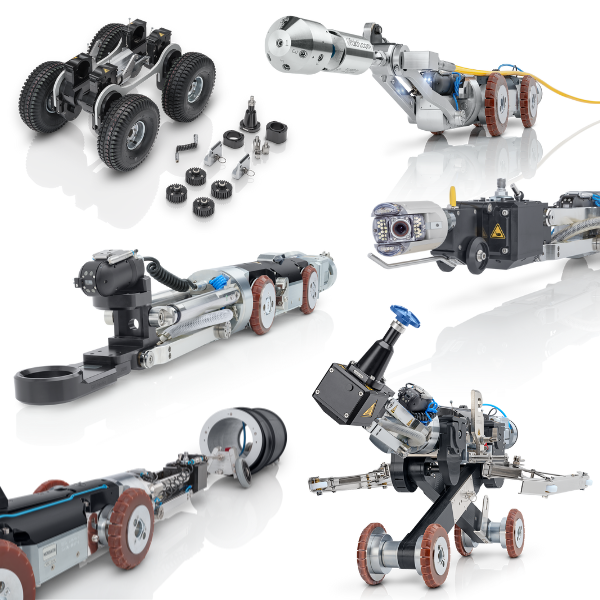

Systematic sewer rehabilitation: Cutting and rehabilitation systems for use in main sewers

With the powerful cutting and rehabilitation robots, economical repair procedures can be carried out efficiently and trenchlessly to improve the condition in the long term and preserve the asset value for future generations.

The spectrum of applications ranges from patching, reinstating connections after liner insertion, removing deposits with cutting tools or ultra high pressure water jetting technology to packer-guided sealing, injection and coating tasks.

Reasons for sewer rehabilitation

There are various causes and resulting damage patterns that can impair the functionality of the pipes and lead to defects.

- Corrosion and wear: Chemical influences damage the inner surfaces of the pipes.

- Deformation and destruction: Deformation and destruction mostly occur as a result of earth movements, which are related, for example, to insufficient compaction of the lower or lateral bedding zone of the pipe. Cracking occurs and, with further stress, fragmenting and collapse of the pipe.

- Leaky joints and connections: These are due to design weaknesses, but also in particular to faulty installation. The result is exfiltration, infiltration and also root ingrowth.

- Obstructions and deposits: Obstacles such as root ingrowth, protruding connections, crossing pipes or objects that have fallen in affect the flow and the function of the pipes just as much as deposits.

MicroGator Air

MicroGator Air

The pneumatically driven cutting and rehabilitation system can be operated as a vehicle installation or as a mobile unit.

When used in main sewers of DN 200 (relined) upwards, the cutting robot achieves a working range of up to 300 metres.

Inspection systems can be operated on the same installation.

Decisive advantages of the cutting and rehabilitation systems

- Effective cutting: Through precise control of the cutting process

- Reliable in operation: Power-driven low-noise or pneumatic operation

- Safe investment: Flexible and future-proof thanks to modular system design

- Added value: Installation of top hats and sleeves, grouting, ultra high pressure cutting and inspection

- Ready for immediate use: Turnkey solutions

- Smooth workflow: Better performance and safety thanks to technology and software platform from a single source

Suitable accessories for every application

- Cutting tools: Interchangeable attachments for every material type

- Cutter camera: For precise work and for inspection and documentation

- Observation cameras: Free view into the sewer to the front and rear

- Inspection with the ORION: Enables professional inspection before and after rehabilitation without an additional inspection vehicle

- Installation of top hats: Precise insertion and alignment of top hat liner packers

- Installation of sleeves: Accurate placement and positioning of packers for installing liner sleeves

- Grouting: Accurate placement and positioning of grout injection systems

- Water jet cutting: Efficient removal of large-area deposits with ultra high pressure water jet technology

- Tractor attachment: For operation in large-diameter pipes