Profile analysis and deformation measurement with laser technology

Structures in sewer systems have to meet high requirements. They are subjected to a variety of loads that can lead to damage. These include deformations of the pipe profile.

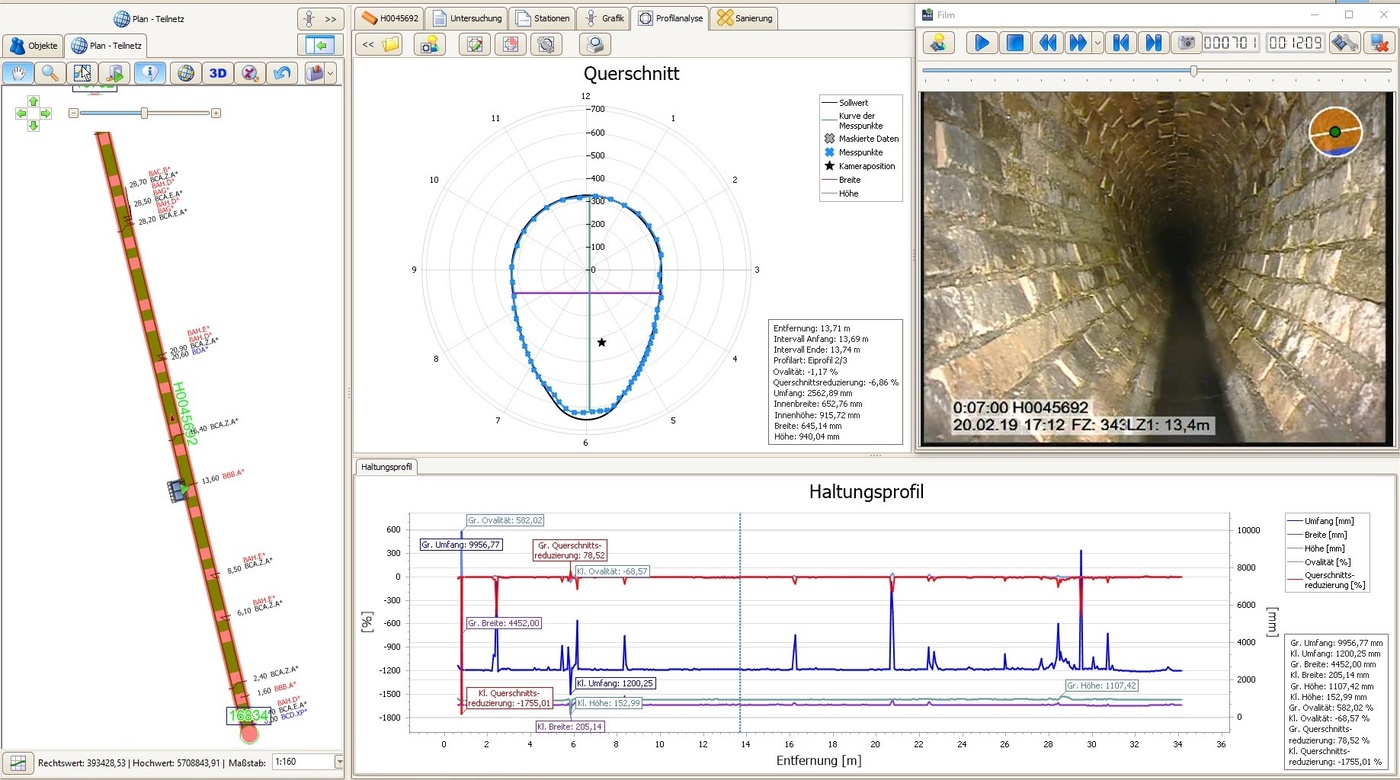

With the help of continuous, laser-based profile analysis and deformation measurement, consequential damage caused by pipe or sewer deformations in circular and ovoid profiles can be detected at an early stage and thus be avoided or economically repaired.

In addition, the measurement results from the LaserScan serve as a basis for rehabilitation planning as well as for the selection and dimensioning of pipe liners.

Ideal application areas for profile analysis and deformation measurement

- Collection and completion of inventory data

- Determination of the actual structural condition

- Determination of deviations, distortions and deformations

- Determination of changes of dimension in sewer reaches with circular and ovoid profiles

- Selection of suitable pipe liners dimensioned to suit the real pipe profile

- New construction and warranty inspections and quality assurance

Fast, precise capture of profiles

For the LaserScan measurement, the camera is aligned with the inner pipe wall so that the distance to the camera is determined on the basis of two laser points. The entire profile is measured and any deviations in the sewer reach are recorded while the equipment is reversing out of the pipe with the camera simultaneously rotating. The data is then evaluated by the software and output in the form of a report and graphics.

Decisive advantages of profile analysis and deformation measurement

- Complete surveying performance: Reliable determination of the real profile dimension over the entire course of a section between manholes

- High measuring accuracy: Changes in the profile dimension can be determined precisely

- Efficient workflow: Profile measurement can be performed in the same operation as the inspection on the return trip

- Optimal use of resources: Analysis can be carried out directly on site or in the office

- Simple evaluation: Intuitive handling of the software and support during data input

- Relevant measurement areas: Areas that are irrelevant for the measurement (e.g. standing water) are hidden

- Practical data integration: Clear combination of inspection and measurement data in IKAS evolution

Profile analysis with IKAS evolution

The software platform can be modularly expanded to include the functions of profile analysis and deformation measurement. The data is used to gain insights that go beyond purely optical inspection. The results can be visualized with descriptive graphics and output in individually configurable reports.