Artificial intelligence

Automatic condition recording with ArtIST

A functioning sewer system is an important part of our civilization and contributes significantly to environmental protection. Because leaky sewers pollute the soil and our groundwater.

Defects in sewer systems and laterals mean that untreated sewage can exfiltrate into the soil, the groundwater and bodies of water, thereby endangering the environment. The infiltration of extraneous water into the sewer system is also problematic: For one thing, the dilution of wastewater reduces the effectiveness of the treatment plants. For another thing, the greater volume of water can overload sewers, stormwater basins and wastewater treatment plants.

To avoid this, precise knowledge of the sewer systems under the ground is vital. If the condition of the sewers and pipes is known, it is possible to take early action in the event of damage and thus ensure that the value of the sewer system is maintained in the long term.

Our solutions for professional sewer inspection

With the inspection systems designed and produced by IBAK, main sewers, laterals and manholes can be examined in detail and checked for leaks. Sewers are rehabilitated with IBAK's cutting and repair robots. Through the joint development process of hardware and software, the powerful IKAS platform enables customized solutions for every sewer application.

Development and production of sewer and pipe inspection cameras and technology

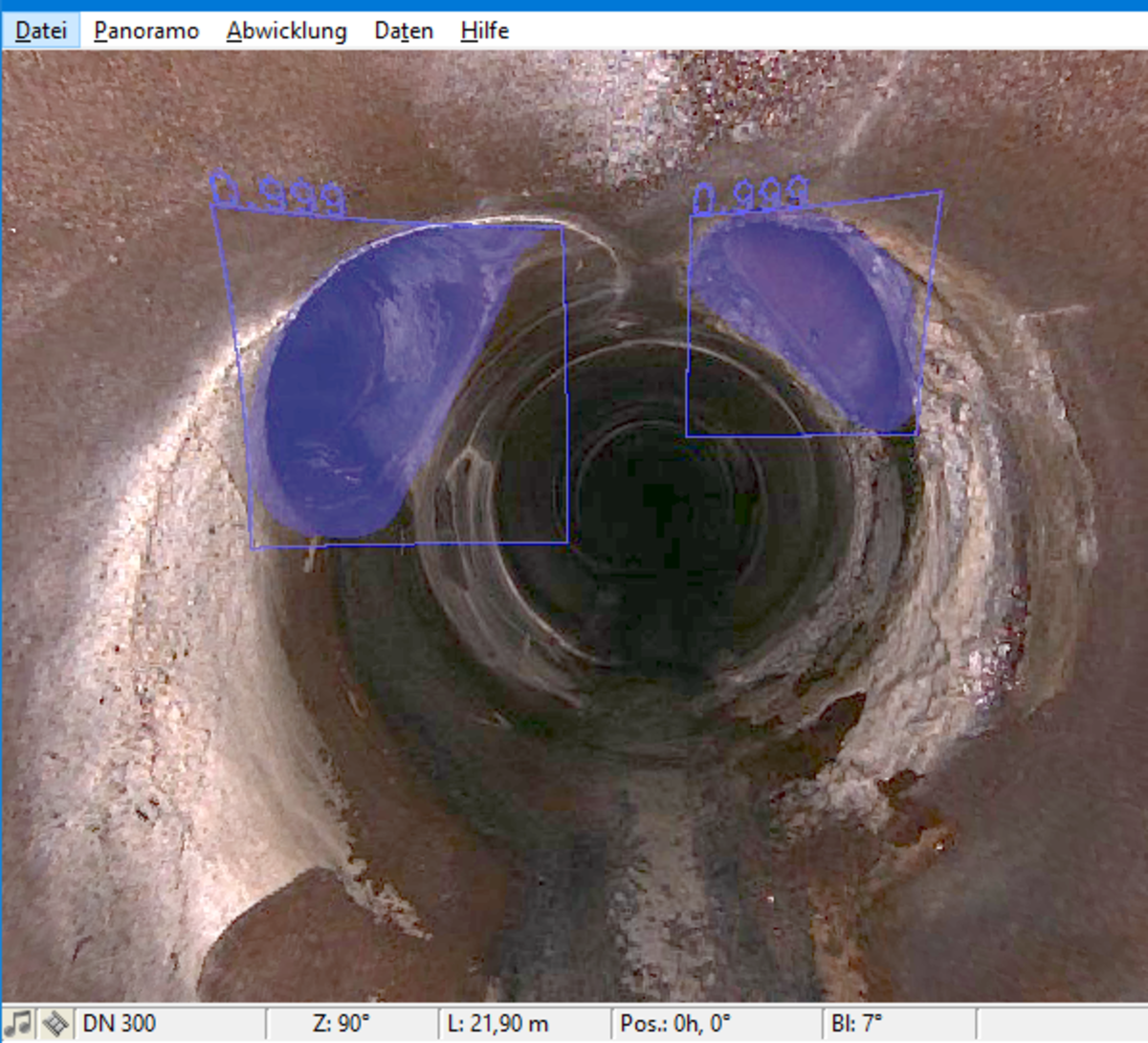

An inspection camera is the centrepiece of every sewer inspection system. Sewer inspection cameras provide high-resolution images and videos, enabling professionals to accurately assess the condition of pipes and identify issues such as blockages, cracks, root intrusions, and corrosion. By utilizing advanced sewer cameras, problems can be detected at an early stage, allowing for targeted repairs and preventing costly damage.

Sewer TV inspections are an essential tool for maintaining the integrity of sewer systems. These inspections help extend the service life of pipelines, reduce operating costs, and minimize the risk of unexpected failures. Modern pipe inspection cameras ensure that no problem remains hidden. This significantly increases the efficiency and accuracy of sewer inspections.

In addition to their diagnostic capabilities, sewer inspection cameras are designed for durability and ease of use. Many models are waterproof, corrosion-resistant, and equipped with long cables to navigate extensive pipe networks. Whether for municipal sewer systems, industrial pipelines, or residential plumbing, these cameras are indispensable for maintaining infrastructure health.

By investing in high-quality sewer inspection camera technology, municipalities, contractors, and plumbing professionals can save time, reduce costs, and ensure the longevity of their sewer systems. With the growing demand for non-invasive inspection methods, sewer cameras are becoming an essential tool for sustainable infrastructure management.

Our solutions for professional sewer rehabilitation

After identifying damage through the sewer inspection, the next step is sewer rehabilitation. Various techniques are used to restore the functionality of the pipes. One frequently used method is the use of milling robots to remove deposits, roots and other obstructions or to reopen connections after pipe liner rehabilitation. The robot can also be used to realise other rehabilitation methods such as placing caps and sleeves.

Another effective technique is ultra-high pressure water jetting. Water is channelled through the pipes at extremely high pressure to remove deposits and blockages. This method is particularly gentle on the pipe structure and enables thorough cleaning, which restores the water flow and prevents future blockages.

Development and manufacture of milling and rehabilitation systems

IBAK develops both electrically and pneumatically operated milling and repair robots for sewer rehabilitation. These versatile systems are used in various areas of sewer maintenance, from damage repair to the preparation and implementation of further sewer rehabilitation measures.

Pure synergy: integrated solutions for sewer inspection and sewer rehabilitation

Sewer camera inspections as part of sewer inspections help to extend the service life of sewer systems and reduce operating costs. In addition, innovative rehabilitation techniques such as the use of milling robots and ultra-high pressure water jetting ensure that sewer systems are maintained efficiently and sustainably

The consistent combination of inspection and rehabilitation technology, coupled with a comprehensive software platform for professional sewer service and sewer operation, creates a holistic solution that meets the individual requirements of the sewer industry.

The modularity of the systems means that inspection and rehabilitation work can be carried out efficiently both in combination and separately. The software solutions for sewers help to analyse, manage and easily exchange the data obtained. This creates a complete picture of the condition of the sewer system, enabling targeted planning of maintenance measures. The holistic approach optimises workflows and ensures consistent quality and cross-system support.

IBAK systems stand for performance, reliability and safety under demanding operating conditions. Our expertise in inspection, rehabilitation and measurement technology and the coordinated software are bringing forwards network operators, service providers and engineering companies all over the world. We pave the way for our customers' success.